Estimated reading time: 5 minutes

What Makes Chillers So Effective?

Commercial chillers are not only environmentally friendly but with the proper set up and maintenance will often use far less energy when operating under full load settings compared to other HVAC systems. Providing your building with reliable air conditioning you can count on time and time again. In fact, Newer models have improved on the existing environmental efficiency and energy savings these systems are able to provide by a great deal with improvements made in VFD’s.

What is a Chillers Purpose?

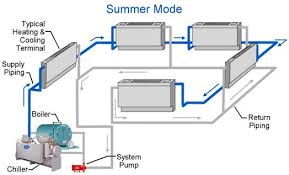

Chillers are specifically designed to handle the largest cooling load during an ordinary year within your facility, this can occur even if that load only happens for a few hours a day. The remainder of the time the chiller system will continue to work on a lesser load.

Chillers run at their highest efficiency when they are operating at or near full-load settings. As the load on the chiller declines, the efficiency of the chiller will oftentimes decline as well.

For commercial buildings that do not generally have a need to operate under full load settings; a chiller system that features a VFD (variable-frequency drive) can greatly aid in lessening the overall amount of energy consumption used during partial load settings. Especially if you consider the fact that chillers are a primary consumer of energy in most commercial buildings today.

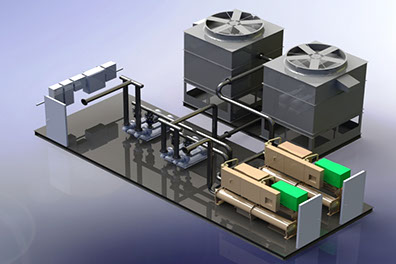

For larger locations that have more than one chiller, operating efficiency can be further improved by staging the function of those chillers based on the building’s load needs. For example, when the cooling load in the building is moderate or low, only one chiller needs to be actively online. As the demand for the cooling load increases, other units can come online to meet the increase in cooling needs as necessary.

That being said, even taking small steps, like keeping your unit properly maintained can have a BIG impact on overall operating efficiency. Translation…more money back in your pocket at months end.

Commercial Chiller Parts – Overview

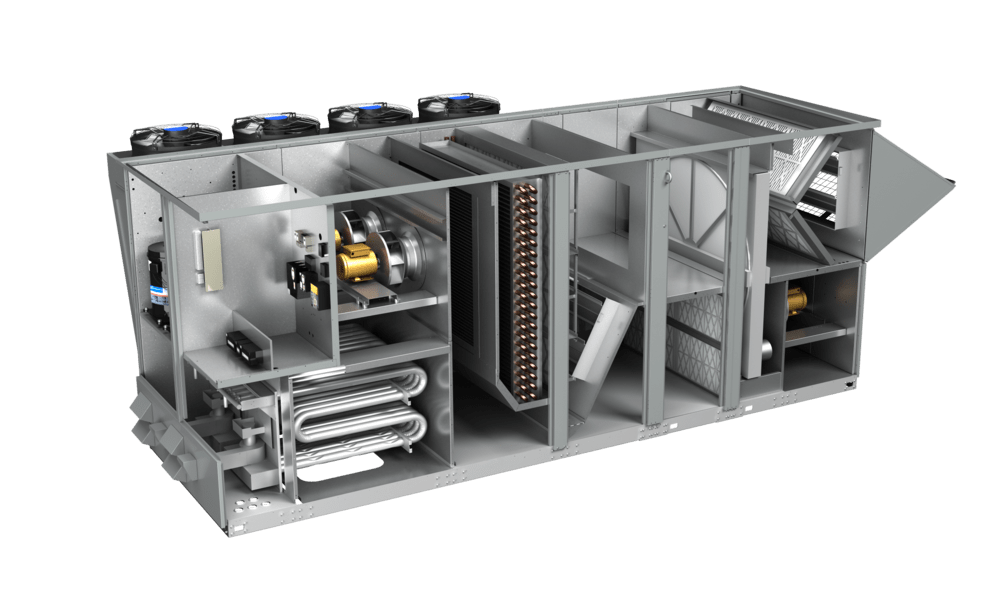

The main components of a chiller are the Compressor, Condenser, Evaporator, Expansion Valve, Power Panel, Water Box and Controls.

Compressor

The compressor is considered a “prime mover”, its main job is to create a pressure difference which will allow the refrigerant to move around the system as needed. The compressor for your chiller is always located between the evaporator and the condenser. It is important to note that the compressor can be extremely noisy, hearing protection should always be worn when in close proximity of the chiller.

Condenser

There are two main types of condensers, they are air-cooled and water-cooled. Your chillers condenser is generally located after the compressor but before the expansion valve. Its main purpose is to remove heat from the refrigerant that was picked up in the evaporator.

Expansion Valve

The expansion valve is located between the condenser and the evaporator. Its purpose is to expand the refrigerant thereby reducing its pressure and increasing its volume. This will then allow it to pick up the unwanted heat in the evaporator. There are many different types of expansion valves, the most common are: the thermal expansion valve, pilot operated thermal expansion valve, electronic expansion valve, and the fixed orifice expansion valve.

Evaporator

The evaporator is located between the expansion valve and the compressor, its purpose is to collect any unwanted heat from the building moving it into the refrigerant so that it can then be sent to the cooling tower. The water cools as the heat is extracted by the refrigerant, thus producing “chilled water.” This chilled water is then pumped around the building and used to provide air conditioning.

Power Unit

The power unit is usually either mounted directly to the chiller or can be found separate from the chiller and mounted to the wall instead. The sole purpose of the power unit is to control the flow of electrical power to the chiller. The power unit will usually contain a starter, circuit breakers, speed controller and power monitoring equipment.

Controls

The controls are typically mounted directly on the chiller itself. Their job is to continually monitor the various aspects of your chiller’s performance and make adjustments as necessary. These control units are designed to generate an alarm to the engineering team(s) as well as to safely shut the system down to prevent damage to the unit.

Water Boxes

Water boxes are mounted to the evaporators as well as the condensers of water-cooled chillers. Their primary purpose is to direct the flow of the water as well as to segregate which directional flow is to be the entrance and exit.

Chillers can be found in most medium to large buildings and will effectively produce the chilled water necessary to provide reliable air conditioning throughout your facility. If you have questions regarding your facility’s chiller, or to have your unit properly serviced or maintained consider reaching out to the pros as Air Dynamics today. We look forward to providing you with high-quality service you know you can rely on!

You Might Also Like:

Resources for Commercial HVAC Savings

Commercial Boilers & How They Work

What is a (VRF) Variable Refrigerant Flow System?

We Service

Abington, Bensalem, Cheltenham, Churchville, Croydon, Elkins Park, Glenside, Holland, Horsham, Huntingdon Valley, Jenkintown, Langhorne, New Hope, Newtown, Philadelphia, Richboro, Southampton, Washington Crossing, Willow Grove, Yardley, and more

Counties Serviced Include:

Bucks, Burlington, Camden, Mercer, Montgomery & Philadelphia